-

CNC High-Speed Drilling Machine

-

CNC Drilling Machine

-

CNC Hydraulic Punching Marking Machine For Plate

-

Beam Band Saw Machine

-

Beam Drilling Line

-

CNC Punching/Drilling Marking Shearing Line For Angle

-

CNC Flat Bar/Channel Process Line

-

Straightening Machine

-

CNC Laser Machine

-

Screen Plate Wholesale

-

Marking Machine

-

Notching Machine

-

CNC Woodworking Machine

-

Other CNC Machine

-

Testing Machine

-

Accessory

-

Mr. BegallTo:Jinan FAST CNC Machinery PLC Dear Sir, With the letter we would like to thank for your cooperation in the successful installation, testing and commissioning of High Speed CNC Drill Of First in its kind Ethiopia , that would enable us do many works especially sugar product tube plate holes of various deameters and thickness. ... With Regards

Mr. BegallTo:Jinan FAST CNC Machinery PLC Dear Sir, With the letter we would like to thank for your cooperation in the successful installation, testing and commissioning of High Speed CNC Drill Of First in its kind Ethiopia , that would enable us do many works especially sugar product tube plate holes of various deameters and thickness. ... With Regards

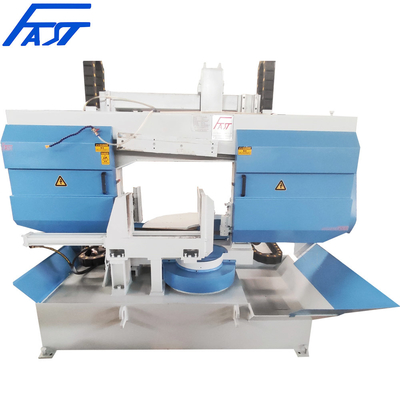

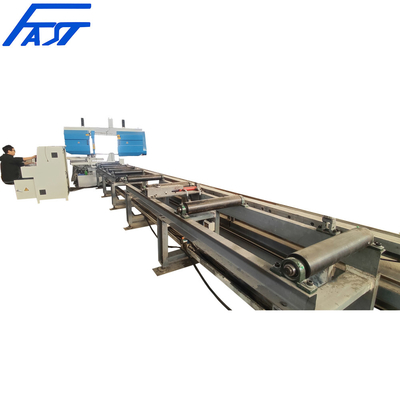

Automatic Industrial Steel Structure CNC H Beam Cutting Production Machine

| Product Name | Band Saw Metal Cutting Machine | Application | Industrial Metal Cutting |

|---|---|---|---|

| Cutting Material | Beams | Function | Cutting |

| Voltage | 380v | Package | Container |

| Certificate | ISO9001 | Sawing H-beam Size | 500*500mm |

| Weight | 8000kg | Rotation Angle (°) | 0~45° |

| Color | Blue and White | |

|---|---|---|

| Machine Size | Customized |

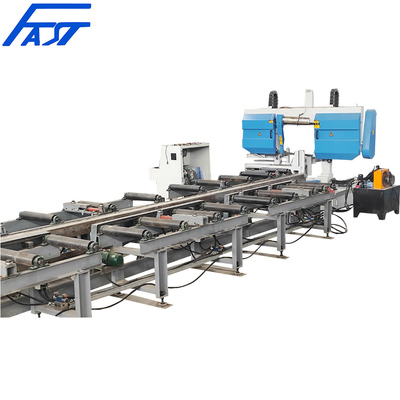

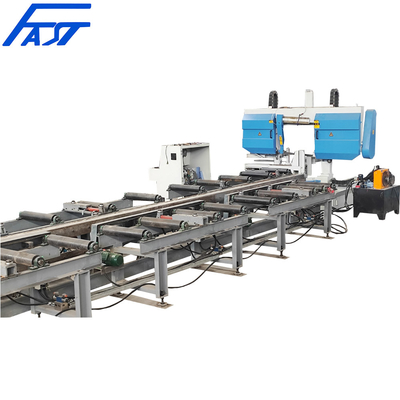

H-Beam Drilling Band Saw Cutting Machine SAW500 With Rotary 0°~45° With Loading And Off Loading Line

![]()

APPLICATION

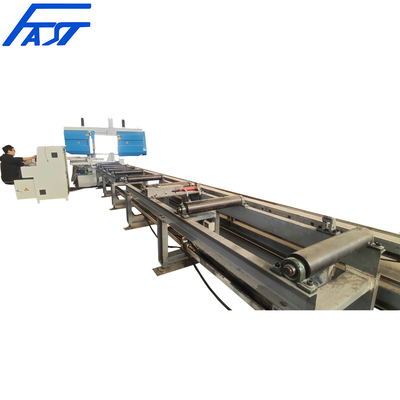

This machine is used for sawing H-beam, steel bar, round steel and other profiles.Narrow saw cutting, high cutting precision, convenient operation and high production efficiency.

This machine is used to cut all kinds of steels. The saw frame can rotate on the platform, which can meet the cutting of all kinds of steel end faces at a certain degree. The degree can be adjusted between 0-45 degrees. It can also cut all kinds of black or non-ferrous metal materials after selecting appropriate processing parameters.

FEATURES

1. This machine can cut all kinds of ferrous metals and non-ferrous metals.

2. The Saw adopts a double column structure to ensure guidance accuracy and stable and reliable sawing.

3. Hydraulic clamping, convenient for clamping materials, suitable for cutting mold materials.

4. The transmission mechanism of the sawing unit is precisely balanced and corrected to reduce vibration and ensure that the saw belt is not easy to break and pull teeth.

5. Lifting cylinders, powerful and stable lifting.

6. The steel wire wheel and the water flow clean chips at the same time, and the saw band has a longer life!

CNC TROLLEY FEEDING SYSTEM

1.Usage

The trolley feeding system is used for the feeding of the CNC section steel, H beam drilling machine. It is mainly used for the transportation of workpieces into the CNC section steel H beam drilling machine processing process.

The workpiece can be H-beam, channel and box beam, etc.

2 Features

1) The trolley feeding system has the functions of automatic stop and alarm when it is blocked,which improves the reliability and safety of the workpiece conveying process.

2) The trolley feeding system adopts rack and pinion transmission mode, which has a simple structure and is easy to install. The feeding length can be determined according to user requirements.

3) Through the high-precision deceleration transmission, the drive motor can easily transport the heavier workpiece to the CNC section steel 3D drilling machine for accurate positioning, and greatly reduce the movement of the workpiece along the conveying direction during the drilling process, improving the machining accuracy.

4) The height of the clamping arm of the trolley feeding system can be adjusted according to the profiles of different specifications, which meets the processing requirements of workpieces of different specifications.

5) The trolley feeding system adopts the method of loosening the clamping device during feeding, and clamping the workpiece when drilling to ensure accurate positioning of the workpiece.

6) The trolley feeding system has the function of automatically measuring the length of the workpiece.

COMPOSITION

| Workpiece Lifting | Loading Trolley |

| Horizontal Storage Rack | CNC Feeding Trolley |

| CNC Trolley Running Conveyor | Loading Roller Conveyor |

| Sawing Unit | Offloading Roller Conveyor |

| Hydraulic Power Station | Electrical Control System |

TECHNICAL DATA

|

MODEL |

G500 |

|

Maximum sawing range |

0°: 500 , 550W×500H 5°: 500 , 500W×500H 45°: 350 , 350W×500H |

|

Band saw blade cutting line speed |

40/60/80m/min |

|

Feed speed adjustment method |

Hydraulic stepless speed regulation |

|

Clamping method |

Vise hydraulic clamping |

|

Bandsaw blade specifications |

1.3×41×5550mm |

|

Band saw blade tensioning method |

Hydraulic tension |

|

Angle rotation method |

Hydraulic, magnetic scale measurement |

|

Locking method |

Hydraulic |

|

Main motor power |

5.5Kw |

|

Hydraulic motor power |

1.5Kw |

|

Cooling pump motor power |

0.09Kw |

|

Control method |

PLC+Touch screen |

|

Hydraulic tank capacity |

60L |

|

Cooling box capacity |

100L |

|

Saw size |

2400*2000*2050mm |

|

Saw weight |

2400kg |

|

Cooling system |

Automatic circulating coolant |

|

power supply |

3PH/380V/50HZ |

|

Sawhorse lift |

Hydraulic |

|

Clean waste chips |

steel wire brush |

|

Saw band inspection |

Proximity switch |

|

Following Spare part |

0.5 meter long roller stand |

|

Following Spare part |

A saw blade |

|

Following Spare part |

Toolkit/Toolbox |

|

Following Spare part |

Operation, Maintenance, Electrical Manuals |

- All of these models can be customized according to customer requirements

DETAIL IMAGES

![]()

![]()

![]()

![]()

![]()

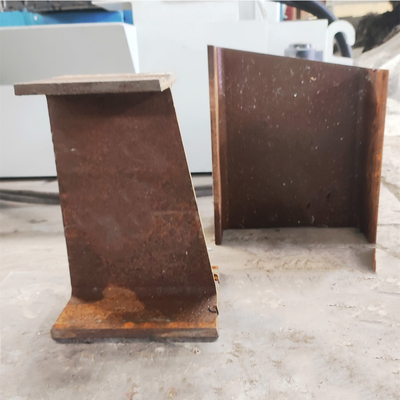

SAMPLES

![]()

![]()

![]()

![]()

![]()

WHY CHOOSE US

![]()

![]()

![]()

COMPANY PROFILE

![]()

COMPANY PROFILE

![]()

WORKSHOP

![]()

CUSTOMER VISIT

![]()

FAQ

![]()

CERTIFICATE

![]()

![]()

PACKING AND SHIPPING

![]()

CONTACT

![]()