-

CNC High-Speed Drilling Machine

-

CNC Drilling Machine

-

CNC Hydraulic Punching Marking Machine For Plate

-

Beam Band Saw Machine

-

Beam Drilling Line

-

CNC Punching/Drilling Marking Shearing Line For Angle

-

CNC Flat Bar/Channel Process Line

-

Straightening Machine

-

CNC Laser Machine

-

Screen Plate Wholesale

-

Marking Machine

-

Notching Machine

-

CNC Woodworking Machine

-

Other CNC Machine

-

Testing Machine

-

Accessory

-

Mr. BegallTo:Jinan FAST CNC Machinery PLC Dear Sir, With the letter we would like to thank for your cooperation in the successful installation, testing and commissioning of High Speed CNC Drill Of First in its kind Ethiopia , that would enable us do many works especially sugar product tube plate holes of various deameters and thickness. ... With Regards

Mr. BegallTo:Jinan FAST CNC Machinery PLC Dear Sir, With the letter we would like to thank for your cooperation in the successful installation, testing and commissioning of High Speed CNC Drill Of First in its kind Ethiopia , that would enable us do many works especially sugar product tube plate holes of various deameters and thickness. ... With Regards

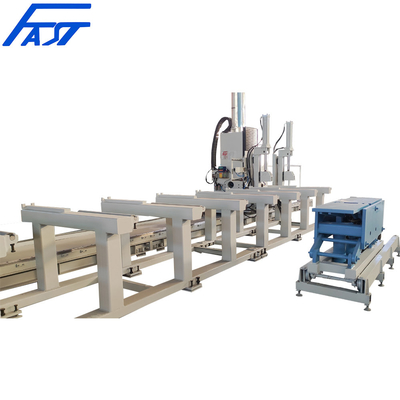

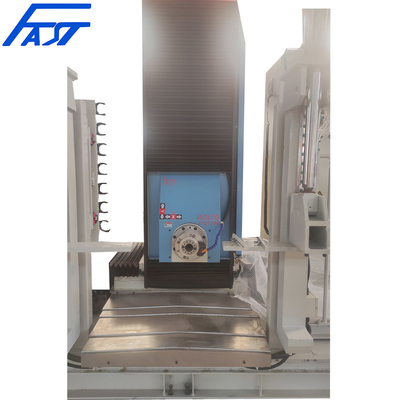

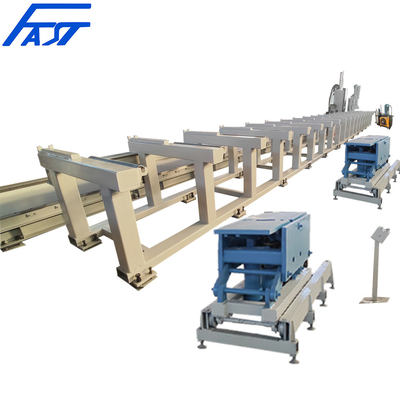

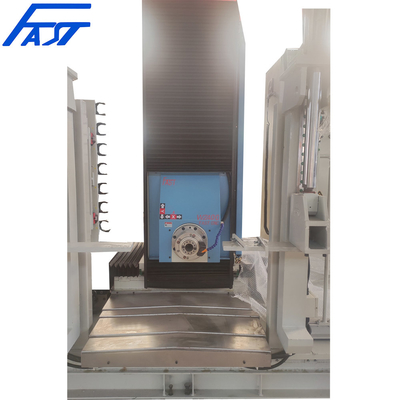

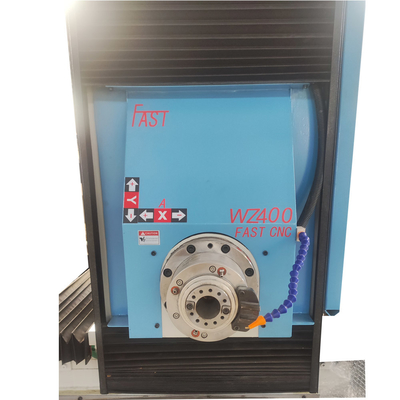

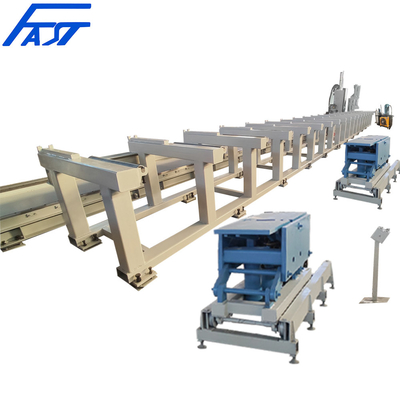

Horizontal Single-spindle Hole Drilling Tapping Milling Engraving Machine for Beams

| Product Name | Beam Horizontal Drilling Machine | After-sales Service Provided | Online Support |

|---|---|---|---|

| Application | Metal Processing | Certification | ISO9001 |

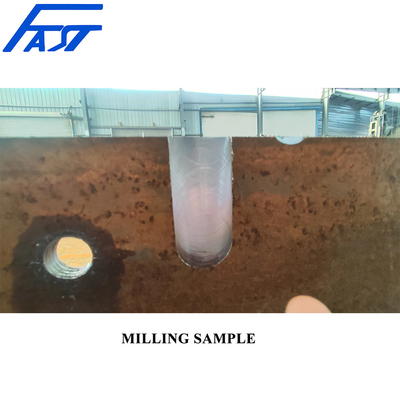

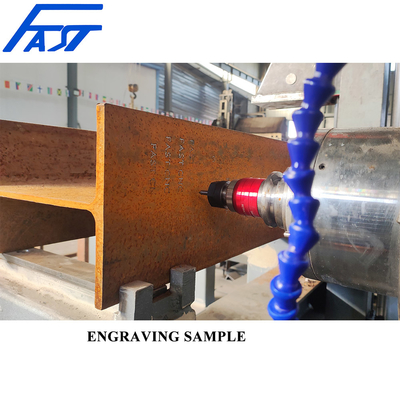

| Max. Drilling Diameter | 50mm | Function | Drilling,Milling,Tapping,Engraving |

| Speed | 3000rpm | Spindle Taper | BT40 |

| Spindle Power | 18kW | Tapping | M27 |

| Machine Color | Blue and White | |

|---|---|---|

| Working size | Customized |

![]()

APPLICATION

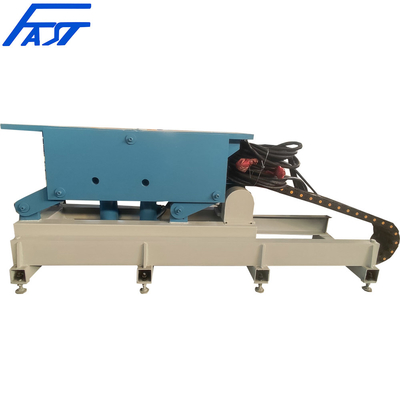

- This machine is mainly used for single-sided drilling of H-shaped steel (L, T-shaped steel), channel steel and square pipe, and is widely used in steel structure buildings, bridges, three-dimensional garages and other industries. The 4+1-axis CNC single-sided drilling machine for profiled steel adopts a structure in which the host moves and the workpiece is fixed.Servo motors realize the positioning of the spindle on the side of the profiled steel, that is, the longitudinal direction and the vertical direction, and the servo feeding of one spindle. The spindle is driven by a servo spindle motor via a pulley and a belt. This machine tool has high hole positioning accuracy and high drilling efficiency, and is an indispensable equipment in the steel structure manufacturing industry.

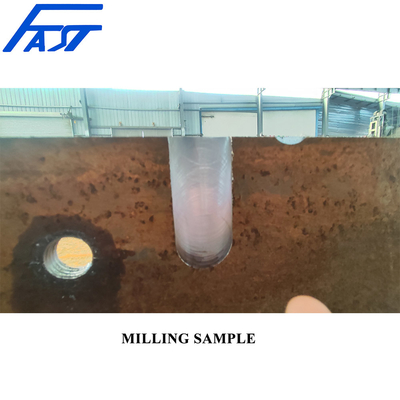

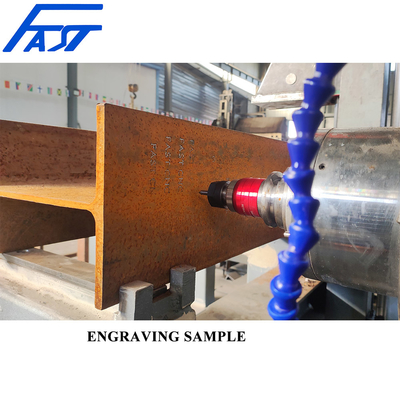

- Machine tool functions: drilling, milling, tapping, scraping.

- The machine can be equipped with a tool magazine.

FEATURES

Craft:

Put the workpiece on the worktable → the workpiece close to the reference side → check whether the tool in the tool magazine meets the processing requirements → tool setting (only when the tool length changes) → start the program to automatically drill holes→ Finished drilling → Take workpiece away from the worktable.

TECHNICAL DATA

|

Name |

Unit |

Specifications |

||

|

H-beam: Max. height × Max. width |

mm |

400×400 |

||

|

H-beam: Max. height × Max. width |

mm |

150×150 |

||

|

Max. Workpiece length |

mm |

14000 |

||

|

Maximum workpiece weight |

kg |

3500 |

||

|

Max. workpiece web thickness |

mm |

≤30 |

||

|

Spindle Qty |

Pc |

1 |

||

|

Spindle end taper |

|

BT40(Pneumatic loose tool) |

||

|

Max. Drilling Diameter |

mm |

10-40 |

||

|

Tapper |

mm |

M27 |

||

|

Spindle power |

kW |

18 |

||

|

Spindle Rated Torque |

Nm |

118 |

||

|

Spindle speed range |

r/min |

0~3000 |

||

|

Spindle feed speed |

mm/min |

0~4000 |

||

|

Spindle feed stroke(Z) |

mm |

500 |

||

|

Spindle axis(Y) |

mm |

400 |

||

|

Clamp positioning axis(X1) |

mm |

14000 |

||

|

Spindle movement stroke(X2) |

mm |

150 |

||

|

Hydraulic clamp opening |

mm |

550 |

||

|

Hydraulic clamp max force |

t |

7 adjustable |

||

|

Working Precision |

Hole distance error in hole group |

mm |

≤±0.2 |

|

|

|

Hole spacing error of adjacent hole groups |

mm |

≤±0.3 |

|

|

Drill cooling method |

Spray cooling, external+inner cooling |

|||

|

Bearing, sliding block lubrication method |

|

Automatic lubrication |

||

|

Worktable Size L×W |

mm |

14500x1200x1000mm |

||

|

Total power |

kW |

About 30 |

||

|

Overall Dimensions L×W×H |

mm |

About 15500×2200×2200 |

||

|

Control Method |

CNC Controlling System |

|||

|

CNC Axes |

4+1 |

|||

|

ATC Automatic Tool Changer |

8 |

|||

DETAIL IMAGES

![]()

![]()

![]()

![]()

![]()

![]()

SAMPLES

![]()

![]()

![]()

![]()

![]()

CLIENTS FEEDBACK

![]()

WHY CHOOSE US

![]()

![]()

![]()

COMPANY PROFILE

![]()

COMPANY PROFILE

![]()

WORKSHOP

![]()

CUSTOMER VISIT

![]()

FAQ

![]()

CERTIFICATE

![]()

![]()

PACKING AND SHIPPING

![]()