-

CNC High-Speed Drilling Machine

-

CNC Drilling Machine

-

CNC Hydraulic Punching Marking Machine For Plate

-

Beam Band Saw Machine

-

Beam Drilling Line

-

CNC Punching/Drilling Marking Shearing Line For Angle

-

CNC Flat Bar/Channel Process Line

-

Straightening Machine

-

CNC Laser Machine

-

Screen Plate Wholesale

-

Marking Machine

-

Notching Machine

-

CNC Woodworking Machine

-

Other CNC Machine

-

Testing Machine

-

Accessory

-

Mr. BegallTo:Jinan FAST CNC Machinery PLC Dear Sir, With the letter we would like to thank for your cooperation in the successful installation, testing and commissioning of High Speed CNC Drill Of First in its kind Ethiopia , that would enable us do many works especially sugar product tube plate holes of various deameters and thickness. ... With Regards

Mr. BegallTo:Jinan FAST CNC Machinery PLC Dear Sir, With the letter we would like to thank for your cooperation in the successful installation, testing and commissioning of High Speed CNC Drill Of First in its kind Ethiopia , that would enable us do many works especially sugar product tube plate holes of various deameters and thickness. ... With Regards

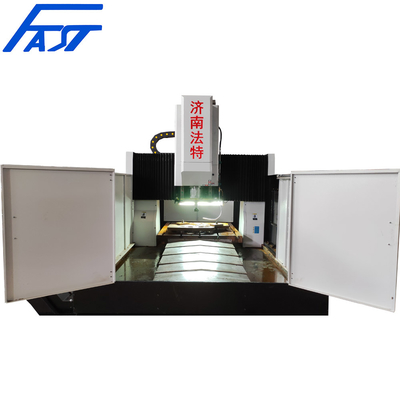

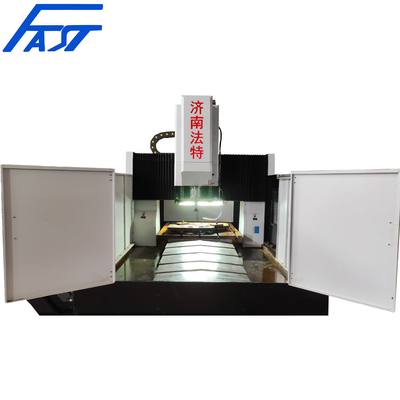

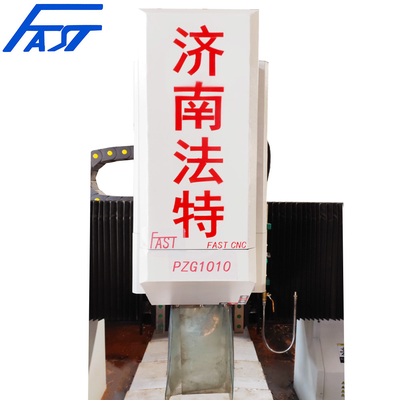

Construction Structure High Speed CNC Plate Drill Machine For Flanges 1000*1000mm

| Product Name | Cnc Drilling Milling Tapping Machine | Keyword | High Speed |

|---|---|---|---|

| Application | Metal Processing | Usage | Structure |

| Function | Drilling Milling Tapping | Spindle Taper | BT50 |

| Certification | ISO9001 | Max. Drilling Diameter | 50mm |

| Color | Black & White | Machine Type | Worktable Movable |

| Mahince Color | Black and White | |

|---|---|---|

| Working size | Customized |

PZG1010-BT50 Factory Sale 1000*1000mm CNC Flange Drilling Milling Machine For Bolier Flange Plate

![]()

APPLICATION

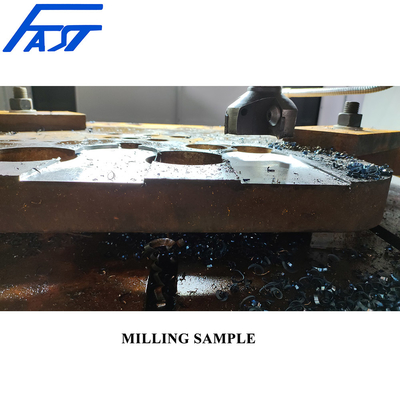

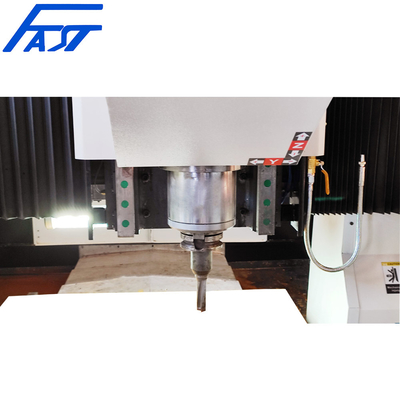

The machine is mainly used for drilling, milling, chamfering and tapping on flanges, tubesheets, and machine bases. Internal cooling high-speed drilling with carbide milling cutters or external cooling drilling with ordinary high-speed steel twist drills, end mills can also be used to mill grooves and special tools are used to mill the expansion grooves of the tube holes of the tubesheet. The machining process of the machine is digitally controlled. The operation is very convenient. It can realize automation, high precision, multi-variety and mass production.

TECHNICAL DATA

PZG1010 Technical Data

|

Name |

Specification |

|

Mode |

Gantry type |

|

Table size (L*W) |

1300*1100mm |

|

Max. workpiece size (L*W) |

1000*1000mm |

|

Distance between the bottom of the spindle to work table |

230~630mm |

|

Processing Capability |

|

|

Max. Drilling Depth |

250mm |

|

Max. Drilling Diameter |

60mm |

|

Milling Diameter |

Milling cutter head diameter 100mm |

|

Drilling Power Head |

|

|

Type of Power Head |

BT50 servo control power head |

|

Quantity |

1 |

|

Type of Clamp |

Butterfly spring pull rod device (air pressure tool) |

|

Spindle Technical Data |

|

|

Spindle Power |

15kW |

|

Spindle Rotating Speed |

30~3000r/min |

|

Type of Connection mold of spindle |

BT50 |

|

Longitudinal movement X Axis |

|

|

Max. Stroke |

1000mm |

|

Speed of X axis |

0~8000mm/min |

|

Servo motor power of X axis |

2.3kW |

|

Transverse movement of Y Axis |

|

|

Max Stroke |

1000mm |

|

Speed of Y axis |

0~8000mm/min |

|

Servo motor power of Y axis |

2.3kW |

|

Vertical Stroke of Z Axis |

|

|

Max. Stroke |

400mm |

|

Feeding Speed of Z axis |

0~5000mm./min |

|

Servo motor power of Z axis |

2.3kW (With brake) |

|

CNC Axes |

4 Axes |

|

Machine Accuracy |

|

|

Positioning Accuracy |

<0.05mm |

|

Re-positioning Accuracy |

≤0.04mm |

|

Verticality of Spindle to work table |

≤0.03mm |

|

Run out of the bottom of spindle and the side spindle |

≤0.02 mm |

|

Pneumatic system pressure |

0.6MPa |

|

Lubrication system pressure |

1.0MPa |

|

Cooling system & filter system |

|

|

Power |

5kW |

|

Flue |

50L/min |

|

Accuracy |

20μm |

|

Inner Cooling System Max. Pressure |

5.0MPa |

|

Out cooling system pressure |

0.2MPa |

|

Outline dimension(L*W*H) |

3200*2000*2600 mm |

|

Total Power |

Appx.30kW |

|

Net Weight |

Approx. 5T |

DETAIL IMAGES

![]()

![]()

SAMPLES

![]()

![]()

![]()

![]()

![]()

WHY CHOOSE US

![]()

COMPANY PROFILE

![]()

COMPANY PROFILE

![]()

WORKSHOP

![]()

CUSTOMER VISIT

![]()

FAQ

![]()

CERTIFICATE

![]()

![]()

PACKING AND SHIPPING

![]()