-

CNC High-Speed Drilling Machine

-

CNC Drilling Machine

-

CNC Hydraulic Punching Marking Machine For Plate

-

Beam Band Saw Machine

-

Beam Drilling Line

-

CNC Punching/Drilling Marking Shearing Line For Angle

-

CNC Flat Bar/Channel Process Line

-

Straightening Machine

-

CNC Laser Machine

-

Screen Plate Wholesale

-

Marking Machine

-

Notching Machine

-

CNC Woodworking Machine

-

Other CNC Machine

-

Testing Machine

-

Accessory

-

Mr. BegallTo:Jinan FAST CNC Machinery PLC Dear Sir, With the letter we would like to thank for your cooperation in the successful installation, testing and commissioning of High Speed CNC Drill Of First in its kind Ethiopia , that would enable us do many works especially sugar product tube plate holes of various deameters and thickness. ... With Regards

Mr. BegallTo:Jinan FAST CNC Machinery PLC Dear Sir, With the letter we would like to thank for your cooperation in the successful installation, testing and commissioning of High Speed CNC Drill Of First in its kind Ethiopia , that would enable us do many works especially sugar product tube plate holes of various deameters and thickness. ... With Regards

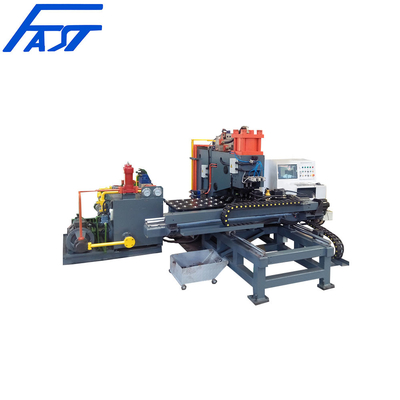

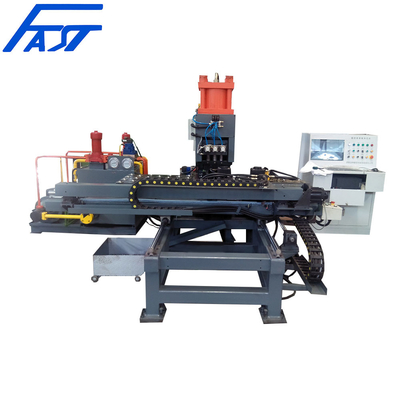

CNC Steel Plate Punching Marking And Drilling Machine Model CJ103

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| After-sales Service Provided | Engineers Available To Service Machinery Overseas | Condition | New |

|---|---|---|---|

| Application | Metal | Voltage | 380v |

| Weight | 3000kg | MOQ | 1 Set |

| Package | Film | Port | Qingdao Port |

| Warranty | 12 Months | Overall Dimension L*W*H (mm) | 3200*2520*1875 |

| Name | Specification | |

|---|---|---|

| Color | Black & White | |

| Controlling System Language | English (Option: Russia) |

APPLICABLE

This machine is used for punching and marking on connecting plates in iron tower and steel structure industries. It can also be used for punching and marking of sheet metal processing in other industries.

FEATURES

- The machine body is a C-shaped steel plate welded structure, which has good rigidity and large processing space. This machine is equipped with three mold positions (including a marking workstation. The mold position switching is performed automatically.

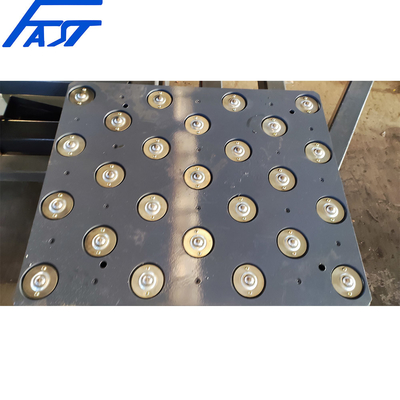

- The clamping system can adapt to different thicknesses workpieces, with a reference zero stop. The workpiece is supported by a rolling ball table.

- The operation of X-axis and Y-axis is driven by servo motor and ball screw. Dual-axis numerical control system controls punching position. The whole processing process is automatic. The operator inputs the size of the workpiece into the computer, which can be called repeatedly in the future;

- Adopting numerical control system, servo motor feeding, high efficiency, stable workpiece punching accuracy;

- The main functional components adopt modular assembly, which is convenient for maintenance;

- Easy programming, input hole size, position, number of workpieces. The operator can also use the program generated by the lofting software, or adopt CAD/CAM direct conversion, providing network port, can share data resources with technical departments to form a local area network;

- With fault self-diagnosis function;

- Punching and marking can be realized on the same board; it improves production efficiency and reduces labor intensity of workers;

- Key hydraulic, pneumatic and electrical components are imported;

- The hydraulic station adopts water cooling.

TECHNICAL DATA

| Model | CJ103 | CJ104 | CJ121 | CJ123 | |

| Max. Size of Work Piece L*W (mm) | 1500*800 | 1500*800 | 1500*800 | 1500*800 | |

| Max. diameter of punching (mm) | Φ32 | Φ32 | Φ40 | Φ40 | |

| Plate Thickness of Punching (mm) | 5~20 | 5~25 | 5~25 | 5~25 | |

| Max. diameter of Drilling | Φ50 | ||||

| Punching Force (kN) | 1000 | 1000 | 1200 | 1200 | |

| Marking Force (kN) | 1000 | 1000 | 1200 | 1200 | |

| Min. Distance Between Hole And Plate Edge (mm) | Punching | 25 | 25 |

30

|

30 |

| Drilling | Depends on hole diameter | ||||

| Dimensions of Characters (mm) | 14*10*20 | 14*10*20 | 14*10*20 | 14*10*20 | |

|

Quantity of Characters |

14/18 | 14/18 | 14/18 | 14/18 | |

| Die-Stations | 3 | 4 | 1 | 3 | |

| Feeding Speed of Drilling (mm/min) | 20~280 | ||||

| Strok of Drilling Spindle (mm) | 180 | ||||

| Rotation Speed of Drilling Spindle (r/min) | 100~750 | ||||

| Precision | Accordance with GB2694-2003 | Accordance with GB2694-2003 | Accordance with GB2694-2003 | Accordance with GB2694-2003 | |

| Programming Mode | Input by keyboard, RS232 interface, floppy disk and USB interface | ||||

| Overall Dimension L*W*H (mm) | 3200*2520*1875 | 3500*2520*2600 | 3700*2520*1875 | 3700*2520*1875 | |

| Model | CJ80 |

CJ161/ CJ163 |

CJ201/ CJ202/ CJ203 |

CJ301 |

| Max. Size of Work Piece L*W (mm) | 4000*1800 | 1500*800 | 1500*1500 | 1850*1850 |

| Max. diameter of punching (mm) | Depends on Workpiece Thickness | Φ50 | Φ50 | Φ60 |

| Plate Thickness of Punching (mm) | 2~10 | 5~25 | 5~30 | 5~30 |

| Punching Force (kN) | 800 | 1600 | 2000 | 3000 |

| Marking Force (kN) | 800 | None | None | None |

|

Min. Distance Between Hole And Plate Edge (mm)

|

20 | 30 | 25-35, Φ≤37mm; 35~50,37mm<Φ≤60mm | |

|

Dimensions of Characters (mm)

|

14*10*12 | None | None | None |

|

Quantity of Characters |

14 | None | None | None |

| Die-Stations |

1 ~ 7 By Customer’s Request |

1/3 | 1/2/3 | 1 |

| Precision | Accordance with GB2694-2003 | Accordance with GB2694-2003 | Accordance with GB2694-2003 | Accordance with GB2694-2003 |

★ All of these models can be customized according to customer requirements.

DETIAL IMAGES

![]()

![]()

![]()

![]()

COMPANY PROFILE

![]()

WORKSHOP

![]()

CUSTOMER VISIT

![]()

FAQ

![]()

CERTIFICATE

![]()

PACKING AND SHIPPING

![]()