-

CNC High-Speed Drilling Machine

-

CNC Drilling Machine

-

CNC Hydraulic Punching Marking Machine For Plate

-

Beam Band Saw Machine

-

Beam Drilling Line

-

CNC Punching/Drilling Marking Shearing Line For Angle

-

CNC Flat Bar/Channel Process Line

-

Straightening Machine

-

CNC Laser Machine

-

Screen Plate Wholesale

-

Marking Machine

-

Notching Machine

-

CNC Woodworking Machine

-

Other CNC Machine

-

Testing Machine

-

Accessory

-

Mr. BegallTo:Jinan FAST CNC Machinery PLC Dear Sir, With the letter we would like to thank for your cooperation in the successful installation, testing and commissioning of High Speed CNC Drill Of First in its kind Ethiopia , that would enable us do many works especially sugar product tube plate holes of various deameters and thickness. ... With Regards

Mr. BegallTo:Jinan FAST CNC Machinery PLC Dear Sir, With the letter we would like to thank for your cooperation in the successful installation, testing and commissioning of High Speed CNC Drill Of First in its kind Ethiopia , that would enable us do many works especially sugar product tube plate holes of various deameters and thickness. ... With Regards

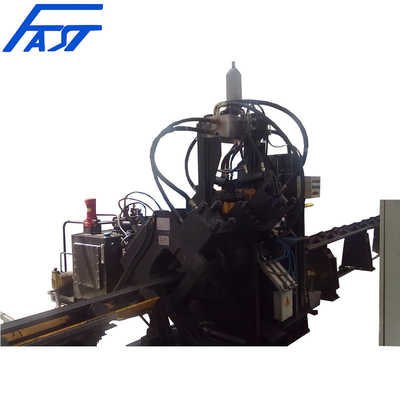

APM1616 CNC High Precision Angle Punching Marking And Cutting Machine Angle Production Line Angle Tower Transmission Lin

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Condition | New | Warranty | 12 Months |

|---|---|---|---|

| Port | Qingdao Port | MOQ | 1 SET |

| Service | 24 Hours Online Services | Voltage | 380V |

| Certificate | ISO9001 | Weight | 15000Kg |

| Overall Dimension (m) | About 23*7*2.4 | Function | Marking, Punching, And Shearing |

| Name | Specification | |

|---|---|---|

| Color | Black & White | |

| Controlling System Language | English (Option: Russia) |

APM1616 FASTCNC Angle Iron Shearing Marking Punching Machine For Power Transmission Tower

![]()

APPLICATION

This machine is mainly used for angle steel marking, punching, and shearing special machine for fully automated production. It is widely used in power towers, communication towers, three-dimensional garages, steel structure buildings and other industries.

FEATURES

- Integrated machine with mechanical, electrical and hydraulic elements;

- There are three sets of punching dies on the two wings of the angle steel. All the holes on the angle steel can be processed in one pass;

- Single-edged cutting saves raw materials and cuts the surface neatly;

- The quasi-distance can be set arbitrarily, and the number of punching rows is not limited;

- The marking unit adopts a closed bed structure, which has good rigidity. Four groups of selected programming on the upper marking box. The marking distance can be set at will;

- The hydraulic system mainly completes punching, cutting, marking, pressing and marking box interchanging;

- The control system is composed of a host computer, servo motor, PLC, external detection sensor, etc.;

- The CNC feeding trolley is driven by a servo motor with high positioning accuracy. The structure adopts a linear guide rail and hard racks, which has a long life and a more stable performance;

- There are various input methods, such as keyboard and mouse input, USB interface input, network interface input.The data generated directly by the 3D or 2D software.

- The main electrical control components and hydraulic and pneumatic components are imported accessories;

- Providing G-code software program that can directly convert CAD graphics into executable machine ;

- Graph display of processed parts;

- With fault self-diagnosis function.

COMPOSITION

| Material platform | Cross feeding conveyor |

| CNC feeding trolley | CNC conveyor |

| CNC marking unit | CNC punching unit |

| Retainer(supporting material) | CNC cutting unit |

| Outfeeding conveyor | Hydraulic station |

| Controlling system |

TECHNICAL DATA

| Model | JX1412 | JX1412-2 | JX1412-3 |

| Function | Punching, Marking,Shearing | ||

| Angle Size (mm) | 40*40*3~140*140*12 | 40*40*3~140*140*12 | 40*40*3~140*140*12 |

| Max. Punching (D*T) (mm) |

Φ26x12

|

Φ26x12 | Φ26x12 |

| Punching Force (kN) | 630 | 1000 | 1000 |

| Marking Force (kN) | 700 | 1000 | 1000 |

| Shearing Force (kN) | 900 | 1600 | 1600 |

| Max. Length of blank(m) | 12 | 12 | 12 |

| Max.length of finished (m) | 8 | 8 | 8 |

| Qty. Of punching head on each side (pcs) | 2 | 2 | 3 |

| NO. of Character Group (Piece) | 4 | 4 | 4 |

| Character Size (mm) | 14*10*20 | ||

| Shearing modes | Double blade | Single blade | |

| CNC Axes (Piece) | 3 | ||

| Feeding Speed of Angle (m/mm) | 80 | ||

| Programming Mode | Lofting software or instruction programming | ||

| Overall Dimension (m) | About 23*7*2.4 | About 23*7*2.4 | About 23*7*2.4 |

| Net Weight (kg) | About 15000 | About 16000 | About 16500 |

★ All of these models can be customized according to customer requirements.

DETAIL IMAGES

![]()

![]()

![]()

![]()

WHY CHOOSE US

![]()

COMPANY PROFILE

![]()

WORKSHOP

![]()

CUSTOMER VISIT

![]()

FAQ

![]()

CERTIFICATE

![]()

PACKING AND SHIPPING

![]()