-

CNC High-Speed Drilling Machine

-

CNC Drilling Machine

-

CNC Hydraulic Punching Marking Machine For Plate

-

Beam Band Saw Machine

-

Beam Drilling Line

-

CNC Punching/Drilling Marking Shearing Line For Angle

-

CNC Flat Bar/Channel Process Line

-

Straightening Machine

-

CNC Laser Machine

-

Screen Plate Wholesale

-

Marking Machine

-

Notching Machine

-

CNC Woodworking Machine

-

Other CNC Machine

-

Testing Machine

-

Accessory

-

Mr. BegallTo:Jinan FAST CNC Machinery PLC Dear Sir, With the letter we would like to thank for your cooperation in the successful installation, testing and commissioning of High Speed CNC Drill Of First in its kind Ethiopia , that would enable us do many works especially sugar product tube plate holes of various deameters and thickness. ... With Regards

Mr. BegallTo:Jinan FAST CNC Machinery PLC Dear Sir, With the letter we would like to thank for your cooperation in the successful installation, testing and commissioning of High Speed CNC Drill Of First in its kind Ethiopia , that would enable us do many works especially sugar product tube plate holes of various deameters and thickness. ... With Regards

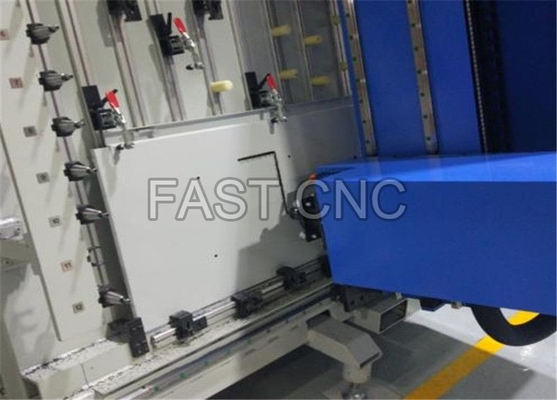

CNC Electrical Cabinets Front Panel Steel Cabinet Drilling Milling Machine PCMC4016

| Condition | New | CNC Or Not | CNC |

|---|---|---|---|

| Warranty | 12 Months | Certification | ISO9001 |

| After-sales Service Provided | 24 Online Services | Spindle Taper | BT40 |

| Brand | FAST | Application | Cabinet Box |

| Model | PCMC 2212(ECNOMIC) | Port | Qingdao Port |

Milling Electrical Cabinets Machine PCMC4016

APPLICATION

At present, in the process of cabinet production, personalized requirements such as hole-opening and tapping are placed at the front of the process chain. This results complicated

management followed up, high production cost and affected overall production cycle. Milling Electrical Cabinets Machine puts hole-opening, tapping and other personalized requirements at the end of the process chain. This not only ensures the efficiency of the cabinet production, but also reduces the cost of management and transportation. At the same time, it gives rapid responses to different users of personalized demands.

Based on the working principle of milling, Milling Electrical Cabinets Machine provides quick responses to small batch production and personalized demands

for the processing of large spray painted boards such as cabinet mounting boards, door boards, and side boards. Also, it provides hole-opening, tapping and marking on cabinet box. This machine is with functions of network communication, automatic tool changing, automatic programming and others. It is able to meet various processing requirements accurately, efficiently, flexibly and quickly.

COMPOSITION

| 1. Slanted bed structure | 2. Work table |

| 3. Moving gantry | 4. Vertical sliding plate |

| 5. Drilling and milling power heads | 6. Tool magazine |

| 7. Electric controlling system | 8. Cooling system |

| 9. Automatic lubrication system | 10. Pneumatic system |

CHARACTERISTICS

● Process by inputting CAD and automatic programming.

● Output NC program and trunking guide list.

● Graphic editing function.

● Automatic tool-changing function.

TECHNICAL DATA

| MODEL | PCMC 2416(ADVANCED) | PCMC 2212(ECNOMIC) |

| Please Ask for Technical Data | ||

|

●Workpiece& material:cabinet door plate, carbon steel 2mm ●Working size: 400*400mm ●Process time: Approx. 6 mins |

●Workpiece& material:RITTAL installation plate, galvanized steel sheet 3mm ●Working size: 1900*900mm ●Process time: Approx. 9 mins |

|

●Workpiece& material:cabinet, carbon steel 2mm ●Working size:1700*600mm ●Process time:Approx. 6 mins/piece |

●Workpiece& material:RITTAL installation plate, galvanized steel sheet 3mm ●Working size:1896*1096mm ●Process time:Approx. 13 mins/piece |

|

●Workpiece& material:cabinet side plate, carbon steel 2mm ●Working size:2100*400mm ●process time:Approx. 7 mins |

●Workpiece& material:small cabinet box, carbon steel 1.5mm ●Working size:400*400mm ●Process time:Approx. 6 mins/piece |

![]()

WHY CHOOSE US

![]()

COMPANY PROFILE

![]()

WORKSHOP

![]()

CUSTOMER VISIT

![]()

FAQ

![]()

CERTIFICATE

![]()

PACKING AND SHIPPING

![]()