-

CNC High-Speed Drilling Machine

-

CNC Drilling Machine

-

CNC Hydraulic Punching Marking Machine For Plate

-

Beam Band Saw Machine

-

Beam Drilling Line

-

CNC Punching/Drilling Marking Shearing Line For Angle

-

CNC Flat Bar/Channel Process Line

-

Straightening Machine

-

CNC Laser Machine

-

Screen Plate Wholesale

-

Marking Machine

-

Notching Machine

-

CNC Woodworking Machine

-

Other CNC Machine

-

Testing Machine

-

Accessory

-

Mr. BegallTo:Jinan FAST CNC Machinery PLC Dear Sir, With the letter we would like to thank for your cooperation in the successful installation, testing and commissioning of High Speed CNC Drill Of First in its kind Ethiopia , that would enable us do many works especially sugar product tube plate holes of various deameters and thickness. ... With Regards

Mr. BegallTo:Jinan FAST CNC Machinery PLC Dear Sir, With the letter we would like to thank for your cooperation in the successful installation, testing and commissioning of High Speed CNC Drill Of First in its kind Ethiopia , that would enable us do many works especially sugar product tube plate holes of various deameters and thickness. ... With Regards

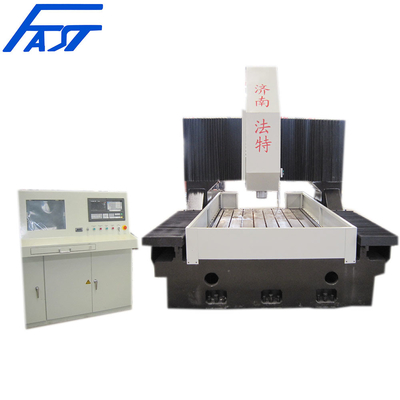

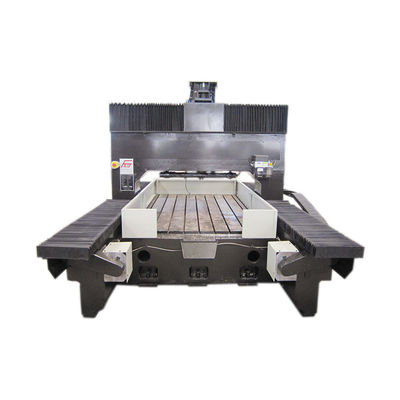

Optimum Jinan FAST CNC Drilling Milling Tapping Machine For Stainless Steel Plates Model PZX2012

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Condition | New | Warranty | 12 Months |

|---|---|---|---|

| Funtion | Drilling Milling Tapping | Max. Drilling Diameter (mm) | Φ 50 |

| Overall Dimension L*W*H (mm) | 2850*2640*2500 | Net Weight (Ton) | 4.6 |

| Certification | ISO9001 | Cnc Or Not | CNC |

| Voltage | 380V | After-sales Service Provided | Engineers Available To Service Machinery Overseas |

High Performance Jinan FAST CNC High Speed Drilling Milling Tapping Machine For Stainless Steel Plates Model PZX2012

![]()

APPLICATION

This machine is mainly used for drilling flanges, tube sheets, baffles and gear rings in petrochemical, boiler, wind power, engineering machinery.etc. It can process through holes and blind holes on single material parts and composite materials. It can also mill pipe holes and expand pipe grooves (using special tools).Also, it can be used for drilling plates in steel structure industries such as construction, bridges, and iron towers. It can realize automation, high precision, multiple varieties and mass production.

FEATURES

1. This machine is fully digitally controlled. CNC system controls servo automatically position and feed to ensure the accuracy of the drilling position;

2. High drilling accuracy CNC drilling power head. It is easy to quantify the depth; It has the functions of drilling blind holes, through holes, reaming and chamfering;

3. There are a number of T-shaped grooves on the workbench, which are used to clamp fixtures and workpieces.

4. Hydraulic clamping locks, not shaking when the power head and gantry drilling;

5. Linear guide line and ball screw fully protected and not exposed;

6. Flat chain automatic chip conveyor & Circulating cooling device;

7. Automatic lubrication device & Protection device. All moving (rotating) parts are automatically lubricated regularly;

8. Anti rusty stainless steel guardrail around the workbench;

9. Gantry beams & columns are widened and all steel plate welded, which is with good rigidity.

10. Full digital numerical control system control:

-Chip breaking function; Tool lifting chip removal function;

-Automatically converting CAD graphics into processing programs function;

- Adjusting the feed and speed according to different apertures,

-The standard numerical control system adopts the German Siemens numerical control system. It is equipped with a USB interface and an LCD liquid crystal display. The operation interface has functions such as human-machine dialogue, error compensation, and automatic alarm.

-Hole position preview and re-inspection function.

COMPOSITION

| Worktable | Movable Gantry |

| Drilling Power Head | Automatic Chip Conveyor |

| Circulating Cooling Device | Automatic Lubrication |

| Hydraulic System | Pneumatic System |

| Electrical System |

TECHNICAL DATA

| Model |

PZ1616 (Option PZ1610) |

PZ2020 (Option PZ2016) |

PZ3030 |

PZ4040 Option PZ4016) |

PZ5050 | ||

| Max. Size of Workpiece (mm) | Max. Processing Range L*W (mm) |

1600*1600(Option 1600*1000) |

2000*2000(Option 2000*1600) |

3000*3000 |

4000*4000(Option 4000*1600) |

5000*5000 |

|

| Max. Drilling Diameter (mm) | Φ 50 | ||||||

| Max. Drilling Depth (mm) |

150 |

200

|

250

|

||||

| Drilling Spindle | Type | Servo controlling power head | |||||

| Quantity | 1 | 1 (option 2) | 2 | ||||

| Spindle Rotation Speed | 30-700 | ||||||

| Spindle Power | 7.5 | 7.5 ( Option 7.5*2) | |||||

| Morse Taper | #4 | ||||||

| X Axis | Max. Stroke | 1600 | 2000 | 3000 | 4000 | 5000 | |

| Speed | 0-6000 | ||||||

| Y Axis | Max. Stroke | 1600 | 2000 | 3000 | 4000 | 5000 | |

| Speed | 0-6000 | ||||||

| Z Axis | Max. Stroke | 350 | 400 | 400 | 500 | 500 | |

| Speed | 0-4000 | ||||||

| Positioning accuracy |

≤ 0.04

|

||||||

| Re-positioning accuracy |

≤ 0.03

|

||||||

| Net Weight (Ton) | 4.6 | 7 | 15 | 28 | 42 | ||

| Overall Dimension L*W*H (mm) | 2850*2640*2500 | 3450*3120*2550 | 4800*4400*2650 | 5900*5400*2850 | 7000*6600*2850 | ||

DETAIL IMAGES

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

WHY CHOOSE US

![]()

COMPANY PROFILE

![]()

WORKSHOP

![]()

CUSTOMER VISIT

![]()

FAQ

![]()

CERTIFICATE

![]()

PACKING AND SHIPPING

![]()